Maximise Performance: How to Select the Right Material for Industrial Hinges

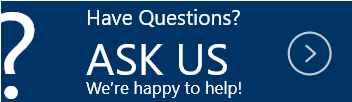

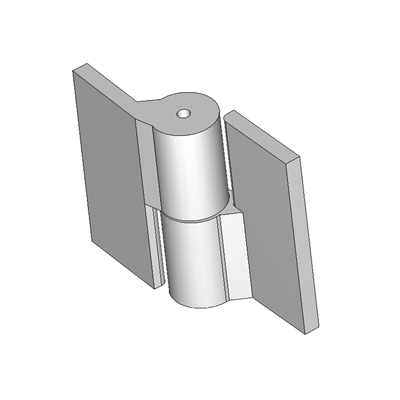

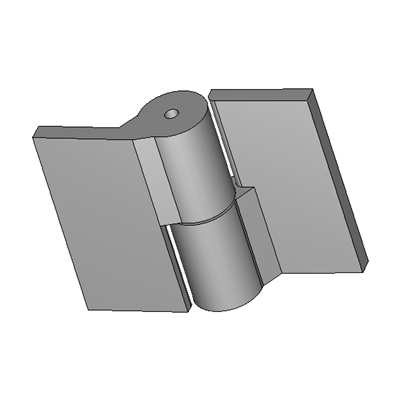

Industrial hinges are heavy-duty hinges that secure doors and gates in various industrial facilities. Needless to say, these hinges must be durable to withstand high traffic, stress, weight, frequent use, and other challenges in these industrial facilities. Choosing the best material for industrial hinges is quite important among various factors. Several hinge materials are available for your consideration, but none may be suitable for your consumption. This post guides you through materials and factors to consider when choosing the best hinge material to secure your heavy-duty doors and gates.

Common Materials for Industrial Hinges

Here are some common materials used for making industrial hinges.

- 304/304L Stainless Steel: 304/304L stainless steel is considered one of the best materials for industrial hinges for its benefits, such as excellent corrosion resistance, strength, durability, and so on. 304L stainless steel has improved weldability and possesses a lower risk of carbide precipitation during welding.

- 316/316L Stainless Steel: 316 stainless steel offers superior resistance against corrosion, pitting, saltwater and chlorides. 316L stainless steel industrial hinges are better for high corrosion and high-temperature applications. Of these two, the 316 has a maximum carbon content of 0.08% and 316L has a carbon content of 0.03%, which helps improve their properties in extreme conditions.

- Carbon Steel: This is one of the strongest hinge materials for industrial applications. Carbon steel has a carbon content of up to 2.5%. This makes carbon steel hinges an ideal choice for applications where strength is required.

Key Considerations for Choosing the Right Material for Industrial Hinges

When selecting the material for industrial hinges, several factors need to be considered

- Environmental conditions: Always consider the environmental conditions when choosing the right material for industrial hinges. If you use hinges in a corrosive environment, like near the ocean or in chemical plants, you can prefer materials like 316/316L stainless steel. If corrosion resistance is a key requirement, 304/304L stainless steel is a good option also.

- Aesthetic and functional considerations: Industrial hinges made from 316/316L are the best option in applications where aesthetics and moisture or chemical resistance are essential.

- Chemical exposure: Industrial settings often involve exposure to various chemicals. So, choose materials that can withstand such exposure without degrading, like 316/316L stainless steel.

- Load and stress requirements: Heavier doors or panels require more robust materials. 304/304L stainless steel and 316/316L stainless steel materials are often chosen for their strength and load-bearing capabilities.

- Cost and availability: While industrial hinges made from different materials offer benefits, assessing the balance between cost and performance is essential.

- 316/316L Stainless Steel: This material is more expensive than 304/304L stainless steel due to its high alloy content. 316 contains a minimum of 2% molybdenum, which improves its corrosion-resistance properties, making it useful against chemicals and saltwater environments.

- 304/304L Stainless Steel: Although cheaper than 316/316L, this material is still more expensive than carbon steel. It is widely considered for various industrial applications.

- Carbon Steel: This material is cheaper than other materials listed here and is widely available. It can be used in applications where high strength is required.

Need assistance choosing the best material for hinges?

If you are still trying to decide what is the best material for heavy-duty hinge applications, you can contact us at Kiesler Machine UK. We regularly design and develop a comprehensive range of heavy-duty hinges for our clients across construction, medical, neutron shielding, HVAC, military and defense industries, agriculture, and security sectors. You can email us at info@kieslermachine.uk or call our hinge design experts at +44 03330062686.

Do you have a design ready? Or need a quote? You can fill out the request a quote form, and one of our experts will contact you shortly.